Innovating responsibly: Altilium and Pfaudler join forces to revolutionise the extractive industry landscape

Innovating responsibly: Altilium and Pfaudler join forces to revolutionise the extractive industry landscape

In a game-changing move towards achieving a more sustainable mineral processing sector, Altilium Group and GMM Pfaudler have joined forces to revolutionise the mineral extraction and processing landscape. This partnership is set to not only streamline operational efficiency and drive costs down; it is a much-needed endeavour to combat and mitigate the environmental challenges inherent to the industry.

Altilium Group, a trailblazer with its innovative DNi Process™, brings a sustainable method of extracting cobalt, nickel and other minerals from laterite ore and processing wastes using nitric acid, to the collaboration. GMM Pfaudler brings in its design and engineering skills in complex and large industrial scale systems solutions together with manufacturing expertise and capabilities in the corrosion-resistant equipment space.

Together, they will unlock untapped wealth in mineral extraction by optimising GMM Pfaudler’s equipment for operating DNi Process™ plants. Additionally, both entities will collaborate in marketing the eco-friendly Altilium technology alongside GMM Pfaudler technology.

Altilium’s technology stands out for its pioneering zero-waste process, eliminating the environmental hazards of wet tailings, containment dams, and sea dumping. This patented process delivers an impressive 99% recovery and reuse of nitric acid.

Moreover, the resulting leach residue, enriched with trace-nitrates, offers the circular benefit of being a fertiliser for rehabilitating and greening mining sites. This underscores the unique features of the DNi Process™ not just as an efficient extraction method but also as a catalyst for sustainable environmental practices in mineral processing.

“Together with GMM Pfaudler and other strategic partnerships, Altilium has significantly enhanced its position in the market,” says Chris Gower, CEO of Altilium Group.

“By leveraging the collective strengths, expertise, and resources of these valuable associations, Altilium is now well positioned to navigate challenges, capitalise on opportunities, and drive innovation in its endeavours. This collaborative approach not only expands Altilium's capabilities but also reinforces its commitment to excellence and success in the ever-evolving landscape of its industry,” he adds.

“At GMM Pfaudler, sustainability has always been at the forefront of our concerns. We have been helping different industries since years to recycle its chemical products and in particular its acids to reuse it in its own process. With our strategic partnership with Altilium and its new DNi Process; we will now give additional arguments to our customers to have cost effective solution to recycle and reuse the nitric acid in their processes. We are really proud to be part of the front runners of the circular economy” says Vincent Leroux, Global VP Technologies and Systems.

The sustained demand for nickel and cobalt, crucial elements in mobile phone and electric vehicle batteries, aligns with the imperative for extracting these resources responsibly.

This is a powerhouse strategic alliance where Altilium and GMM Pfaudler are answering this call for ethical and clean technology while demonstrating their commitment to meeting industry demands and prioritising environmental and ethical considerations.

ABOUT ALTILIUM GROUP

Altilium owns a unique patent-protected process for the extraction of metals from certain ores as well as mine and process waste. Altilium’s intellectual property involves the dissolving of the feed in nitric acid, the extraction of all the metals present, the recovery and reuse of the nitric acid and the resulting residue (if any) being inert, consisting mainly of silicates. The residue will also contain trace amounts of nitrates making it a weak fertiliser, ideal for blending with topsoil to aid site rehabilitation. Nitric acid may be applied to almost any type of feed. In the first instance, Altilium has developed its technology to extract nickel and cobalt (together with the iron, aluminium and magnesium) from nickel laterite ore.

Visit www.altiliumgroup.com to find out more.

For further information contact: chris.gower@altiliumgroup.com

Media contact: mickey@firestarter.live

ABOUT GMM Pfaudler GROUP

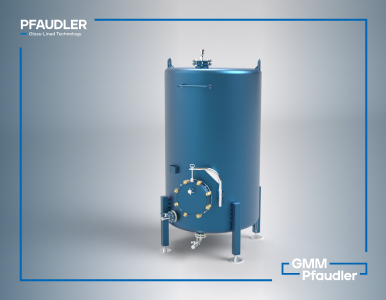

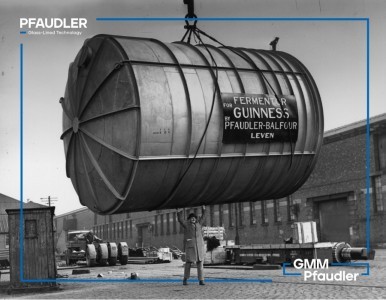

GMM Pfaudler Ltd delivers corrosion-resistant technologies, systems, and services worldwide and remains the preferred choice by consistently providing its customers in the chemical, pharmaceutical and mining industries with innovative and cost effective solutions. GMM Pfaudler has 18 facilities with an extensive sales and service network and employs more than 1,800 people across 4 continents. As part of our global ambitions, we continue to make Big Moves that will allow our people, customers, and the communities we operate in to grow.

More information is available at www.gmmpfaudler.com

For further information contact: Keith.bundil@pfaudler.com

.png)