Spherical Dryers

Mavag Filtration & Drying

Technologies

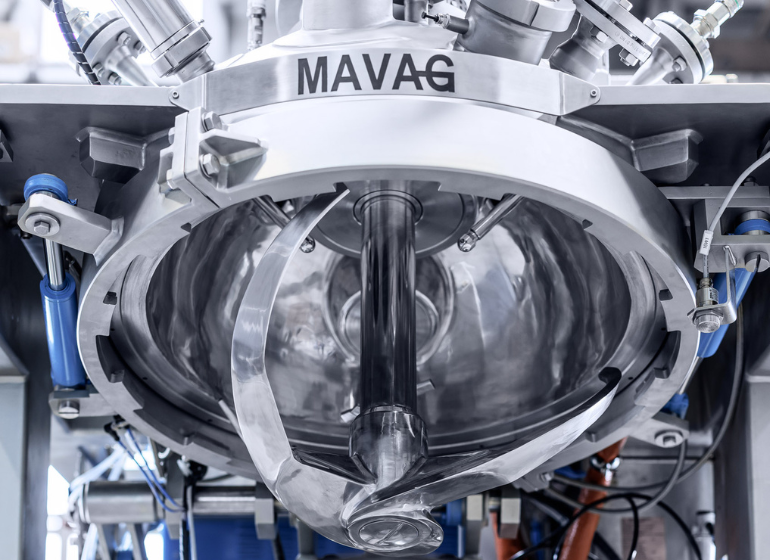

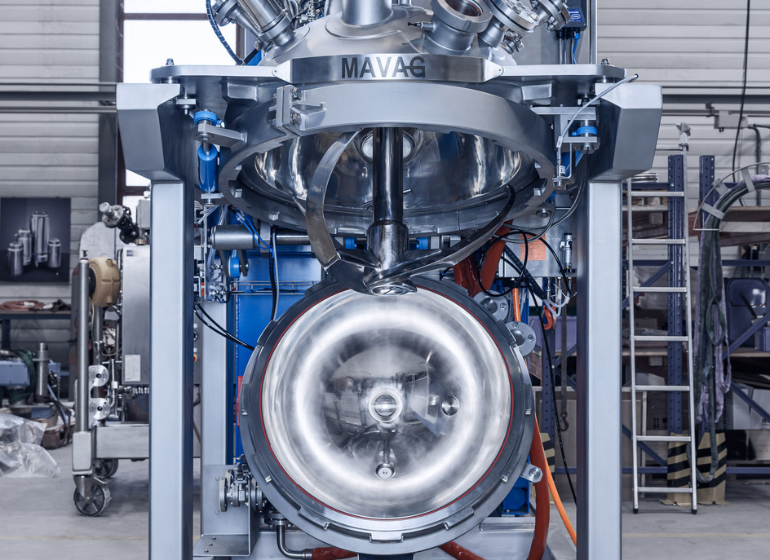

Spherical Dryer

MAVASPHERE®

The Spherical Dryer is a multi-purpose dryer used for drying Active Pharmaceutical Ingredients (API’s) and Fine Chemicals in compliance with cGMP and FDA guidelines.

Mavasphere® ensures excellent drying performance over a wide range of filling capacities with a good turndown ratio.

Key Features and Advantages

- Minimal clearance between the vessel wall and agitator for efficient and uniform drying

- Whole vessel covered by jacket for better heat transfer

- Wide range of filling capacities with a good turndown ratio

- Minimal product hold-up for easy cleaning and validation

- Eccentrically top mounted agitator for uniform mixing and gentle product drying

- Discharge at lowest point for complete product discharge

- Compact system with lower footprint

- Chopper for very effective lump breaking and sticky products

Construction materials

Stainless Steel, Hastelloy, and Special Alloys.

Options

Shaft Sealing Design

- Interseal Dry9000® shaft sealing system

- Gas lubricated double mechanical seal installed outside of the product zone

Agitator

- Hollow heated, rotating 3-blade agitator with minimal clearance between agitator blade and vessel wall.

Bottom Discharge

- Spherical disc valve for quick opening and discharge of dried product with no dead volume.

Standard Accessories

- Lump Breaker, Dust Filter, and Sampling System.

Optional Accessories

- Vessel flange with bayonet type, quick-closing design with hydraulic hinge for easy opening of lower vessel half, allowing for simple inspection and maintenance

- Automation Systems

- Temperature control units (TCU)

- Vacuum and solvent recovery units

- Powder handling / Pack-off systems

Pilot dryers are available for on-site tests, so clients can gain experience with advanced equipment while gathering reliable scale-up and process data.