dry9000® advantages & applications

Interseal Sealing Technology

Technologies

Overview

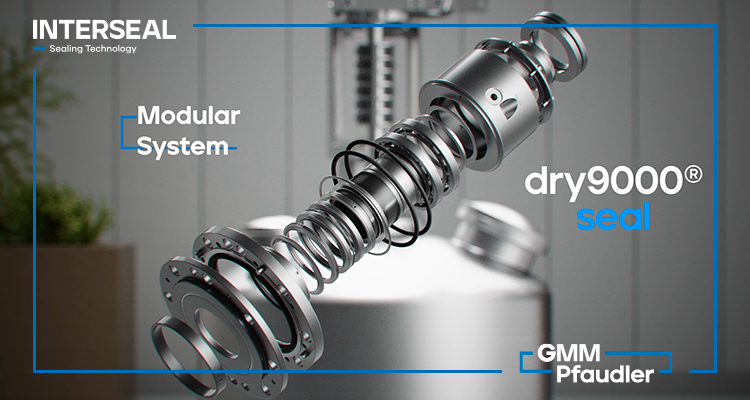

dry9000® can easily be integrated into every machine, regardless of supplier, for pharmaceutical, chemical and food industry. Our sealing technology is a modular concept available in various formats to ensure that every type of production can benefit from all the advantages of our innovative seal.

Main Advantages

- Available as a ready-to-mount cartridge for quick and easy installation;

- Dry-running lip seal - no supply system is required;

- No sudden shutdown through smart monitoring before the second and the last sealing elements;

- Sealing element made of a special bright chemically resistant PTFE compound;

- Lower your TCO (total cost of ownership) thanks to longer lifetime and zero contamination for your product;

- The existing modular spare part system enables you to reduce the quantity of your spare parts on site;

- No start-up requirements.

Compliance with Industry Standards

dry9000® complies with all size and safety standards, including DIN 28138, DIN28154, ATEX (conformity in all zones and temperature classes), TA Luft, GMP, and FDA standards.

Industries served by Pfaudler

The dry9000® lip seal solution can be used in the following sectors:

- Pharmaceutical & Chemical industries

- Petrochemical

- Food & beverage

We have vast experience of a multitude of chemical processes and serve a broad range of industries, including:

- Pharmaceutical

- API and bio-based pharmaceuticals

- Specialty and Fine Chemical

- Acid Recovery

- Pharmaceutical

- API and bio-based pharmaceuticals

- Specialty and Fine Chemical

- Acid Recovery

- Pharmaceutical

- API and bio-based pharmaceuticals

- Specialty and Fine Chemical

- Acid Recovery