Reaction Systems

Systems

Modular Reactor Systems: Turnkey Solutions for Every Chemical Process.

GMM Pfaudler Reactor Systems: Engineered for Excellence

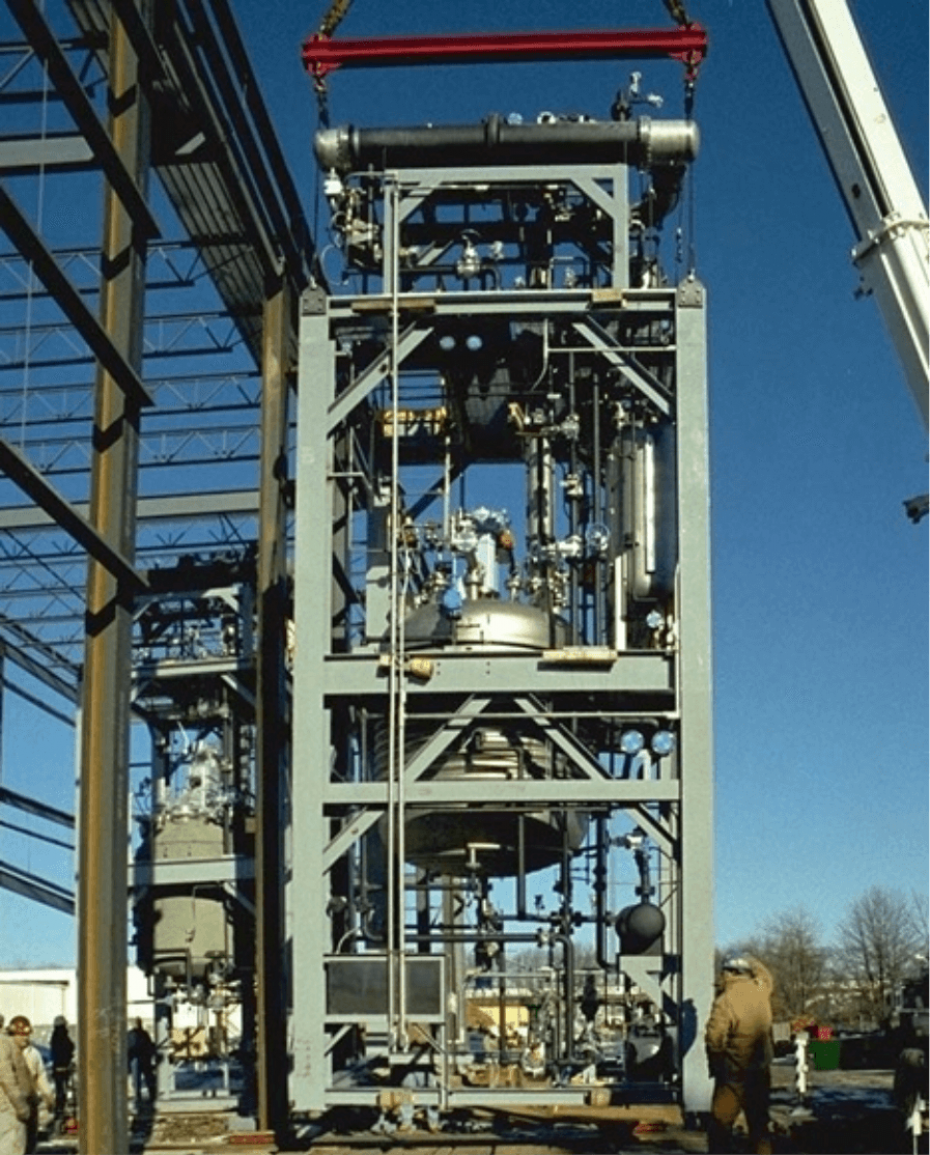

At GMM Pfaudler, we specialize in designing and building turnkey modular reactor systems that are fully integrated, pre-assembled, and customized to your specific chemical process. Our expert engineers develop comprehensive solutions, incorporating all required equipment, instrumentation, piping, and controls to ensure seamless integration and operation. With a focus on efficiency, reliability, and safety, our reactor systems provide superior performance while reducing project timelines and overall costs.

What is a Modular Reactor System?

Each modular reactor system is custom-designed to meet the unique requirements of our clients, delivered as a fully assembled and integrated unit. Typical system components include:

- Engineering & Design: Process engineering, project engineering, project management, construction management, and 3D CAD modeling.

- Core Equipment: Reactors, feed tanks, solids addition systems, condensers, receivers, pumps, exchangers, and columns.

- Control & Automation: PLC control systems, instrumentation, and process and safety interlocks.

- Utility & Support Systems: Solids handling systems, vacuum systems, temperature control units, scrubbers, chillers, cooling towers, and heating systems.

- Structural Support: Skid-mounted steel frameworks for robust, compact, and transportable designs.

- Interconnecting Piping: Fully integrated process and utility piping for seamless system operation.

Reactor Support Systems

When customer central utility systems are unavailable, or lack the capacity for new processes, GMM Pfaudler engineers will design and supply the utilities to support your new reactor system. Our engineers also provide fully integrated support systems for the reactors, such as raw material handling systems, vacuum systems, temperature control systems and scrubber systems.

GMM Pfaudler Turnkey Modular Systems Key Components

Components

- Reactors

- Tanks

- Columns

- Condensers

- Heat Exchangers

- Pumps

- Instrumentation

- Piping

- Solids

- Handling

- Vacuum

- Systems Utilities

- PLC Controls

Specifications

- Equipment Specifications

- Instrument Specifications

- Piping Specifications

- Design Codes

- Construction Codes

- Documentation

Engineering

- Project Management

- Process Engineering

- Project Engineering

- Instrument Engineering

- HAZOP / PHA Participation

- Materials Engineering

- Controls Engineering

Design

- Modular Design

- 3D CAD Modeling

- P&ID

- PFDs

- Structural Drawings

- Fabrication Drawings

- Piping Isometrics

- Piping Orthographics

- Wiring Diagrams

Construction

- Equipment

- Structural Steel

- Piping

- Electrical

- Construction Management

- Factory Acceptance Testing (FAT)

Administrative

- Procurement

- Cost Control

- Schedule Control

- Documentation

Operation

- Site Acceptance Testing (SAT)

- Commissioning

- Guaranteed Performance

- Training

- Parts

- Service

Benefits of GMM Pfaudler Modular Reactor Systems

Our turnkey modular reactor systems offer a range of benefits, making them the preferred choice for high-performance chemical processing:

- End-to-End System Expertise:

Seamless integration of all components for optimal performance. - Fixed Pricing:

Eliminating cost overruns for predictable project budgeting. - Single-Source Responsibility:

Streamlined execution with reduced project risk. - Superior Quality:

High-precision, shop-fabricated construction for long-term reliability. - Faster Project Delivery:

Shortened lead times through modular design. - Cost Savings:

Reduced engineering, fabrication, and installation costs. - Space Optimization:

Compact, efficient footprint for process plants. - Minimal Operational Disruption:

Smooth integration with existing systems, reducing downtime.

Pilot Plant

through

Commercial Scale

_1.png)

Critical Process Design Considerations for Reactor Systems

GMM Pfaudler designs every system to deliver high-quality, repeatable results while minimizing operational costs and ensuring safety. Key design elements include:

- Liquid feed control (weight and/or flow and temperature) for feeding from tanks or drums.

- Solids addition control (weight and/or flow) for charging from bags, drums or super sacks.

- Precise reactor batch temperature control for the highest batch quality and yield and to ensure batch-to-batch repeatability.

- GMM Pfaudler mixing system technologies (Mixion, Mixel, Mixpro, SEMCO brands) provide the optimum level of mixing for proper blending, temperature and reaction control to ensure the highest product quality, whether your process requires simple blending or high viscosity mixing, solids suspension, emulsifying, or other.

- Distillation/stripping control (heat, rate, temperature, vacuum, reflux) for optimum product purification and solvent recovery.

- Condenser temperature control

- Vacuum level control for reduced batch temperature operation.

- Process and safety interlocks are key design considerations to ensure proper and safe operation.

FAQ - Reaction Systems

What components are included in a reactor system?

GMM Pfaudler Systems designs and builds reactor systems as turn-key, completely assembled, process modules that include all necessary equipment, instrumentation, piping and controls required for our clients' processes.

Can I get a custom chemical reactor designed for my process?

GMM Pfaudler does have standard pilot scale reactor systems in borosilicate construction with our Normag brand. However, for commercial scale systems, GMM Pfaudler Systems custom engineers, designs and fabricates every reactor system for each client's specific process and installation site. Our engineers integrally design all system components to provide the most efficient operation system for each specific client process. We also custom design and manufacture the layout of each system to properly fit in each client's available process area, with the system arrangement designed for easy operation and maintenance.

What materials of construction can be incorporated into reactor systems?

With Pfaudler being the inventor and leading manufacturer of glass lined equipment since 1884, GMM Pfaudler Reactor Systems many times includes our glass-lined reactors in the system. However, with our Equilloy alloy fabrication capabilities, our reactor systems are oftentimes constructed of stainless steel and high-nickel alloys and we also construct with fluoropolymer linings/coatings utilizing our Edlon brand.

Can I get turnkey reactor systems?

GMM Pfaudler designs and builds turnkey, modular reactor systems that include the reactor as well as any ancillary equipment required for the chemical process along with all the required instrumentation and controls and the interconnect process and utility piping. The reactor systems are provided completely assembled on structural steel support modules. When the client does not have existing utilities to support the reactor system, GMM Pfaudler engineers design and provide the required utility systems.

Can I get fully automated reactor systems?

GMM Pfaudler designs and builds both manually operated and fully automated systems. For fully automated reactor systems, we provide a PLC control system along with all the instrumentation necessary to monitor and control the process, including process and safety interlocks.

Can I get pilot-scale or commercial-scale reactor systems?

GMM Pfaudler provides benchtop borosilicate glass systems and kilo/pilot-scale systems used for process development and testing as well as full commercial scale systems for production. Often GMM Pfaudler provides a pilot scale system to a client to utilize to perfect the process and then use the process information gathered during pilot trials to scale-up and design/build the required commercial scale system.

Can I get a reactor system that complies with all local and national industry standards, requirements and laws?

GMM Pfaudler engineers and designs all systems to comply with all recognized national codes and standards, including but not limited to ASME, API, ANSI, ASTM, TEMA, AWS, AISC, IBC, OSHA, NEC, NFPA, FDA, cGMP, etc.

How long has GMM Pfaudler been designing and building reactor systems?

GMM Pfaudler has been fabricating reactors since our inception in 1884 and we have been designing and building complete reactor systems since the early 1950’s.

Can I get installation and commissioning support with my reactor system?

GMM Pfaudler engineers come onsite to assist our clients with the installation and commissioning of our reactor systems and assist with training operators. Very detailed installation, startup and operating instructions are included in the manual that is provided with each system.

Can I get spare parts and maintenance for my reactor system?

GMM Pfaudler provides life-cycle support for our reactor systems by providing spare parts as well as onsite service provided by technicians from our Services Group.