High Speed Dispersers

Mixion - Mixing Technology

HIGH SPEED DISPERSERS

Homogeneous dispersion of solid particles in a liquid is typically required for various applications in the process industry and can be achieved by high-speed disperser mixer. For example, in the paint industry, various color pigments are added to the liquid solvent to achieve a homogenous solution in the form of paint as the final product. Such pigments, which are solid particles, are not easily soluble in the liquid solvent and therefore require to be homogeneously dispersed in it.

Similar need of dispersion is achieved during manufacturing of Inks using these dispersers.

Material of Construction: Carbon Steel | Stainless Steel

Applications: Paints, Resins & Inks, Adhesives

| Motor Rating (kW) | Shaft Diameter (mm) | Operating Pressure |

|---|---|---|

| 5.5 - 160 | 50 - 160 | Atm |

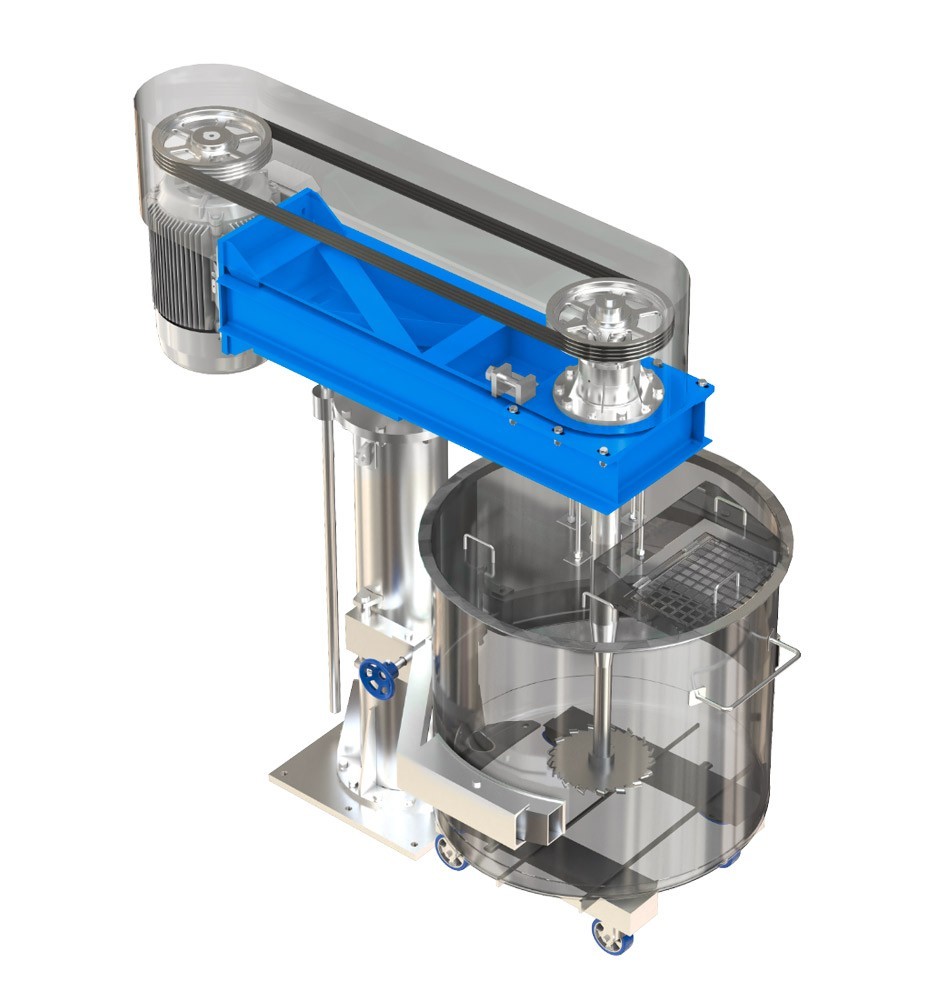

High-speed dispersers can create the desired vortex along with the rigorous turbulent flow. The solids are charged into the vortex zone such that they are immediately dispersed. Depending on the depth of the vortex, the disperser blade i.e. MCD Cowl Disc can be positioned on or off-center. As the fluid viscosity changes, the operating speed of the cowl disc can be varied through an external VFD to maintain the vortex and to improve the dispersion efficiency. High-speed disperser mixers can have one or two dispersion impellers based on the tank geometry.

High-speed disperser design needs to be carefully developed from a mechanical perspective since the operating speeds are generally higher ranging from a few hundred rpm to 2,800 rpm. Such machines need to be low on vibrations, shaft runout, and deflection. Hence, the shafting must be with high precision, balanced, and controlled tuned shaft. Our efficient manufacturing processes help us achieve these mechanical performances.

A High-speed disperser comes with optional features and varied scope on drive arrangement (direct, belt drive), lifting arrangement (mechanical, hydraulic, pneumatic), safety interlock for avoiding starting if no vessel, VFD panel for speed adjustments and trolley mounted tanks. Surface finishes as desired for the wetted part can be offered to suit the applications.