Naro ® Nanofiltration & Reverse Osmosis

Advanced system design to improve solids concentration and permeate recovery

Nanofiltration Reverse Osmosis

Nanofiltration (NF) is a pressure driven process similar to Reverse Osmosis (RO) applied in the area between Reverse Osmosis and Ultrafiltration.

Monovalent ions and low molecular weight organics are passing through the membrane, while bigger compounds are rejected. Monovalent ions and low molecular weight organics are passing through the membrane, while bigger compounds are rejected.

Molecular weight cut off of a Nanofiltration membrane is in the range 150-500 and typical applications are in pharmaceutical preparations, in food and chemical processes, removal of color and hardness from water.

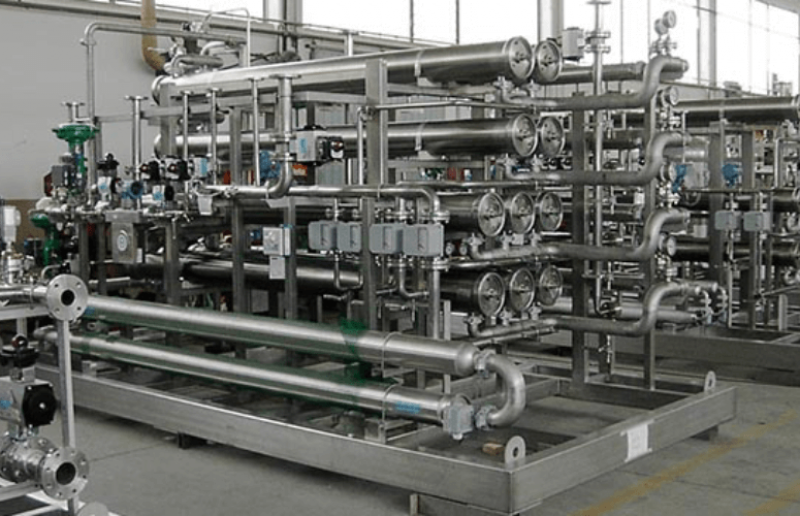

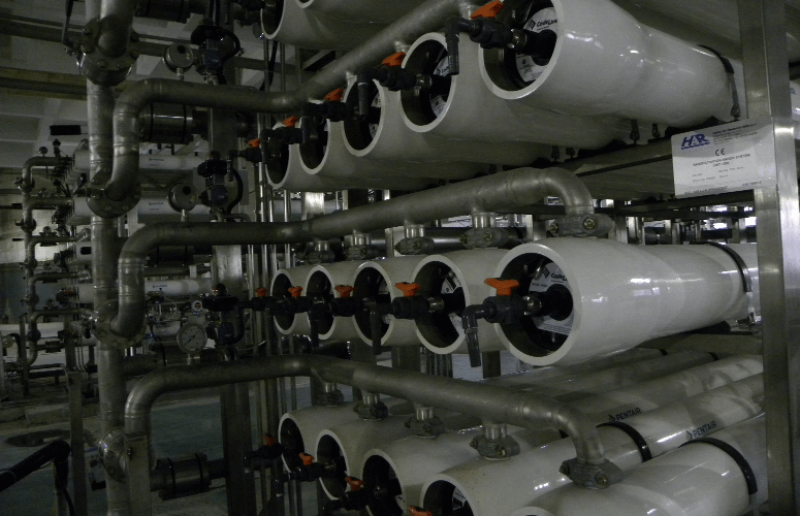

NARO® Technology

Hydroair has developed a reverse osmosis system able to concentrate the total dissolved solids to higher levels than the ones reachable with the traditional reverse osmosis systems, with better energy efficiency and optimal membranes performance.

This system is called NARO® system. NARO® system is a multistage system with feed and bleed configuration, i.e. with continuous discharge of the concentrated phase, that with a variable distribution of the operating pressure in the loops gives the following advantages compared with the traditional systems:

- Lower energy consumption

- Best performance of the membranes, in terms of rejection and fluxes

- Investment and operating costs more competitive

FAQ

Can nanofiltration effectively remove salts and heavy metals from water?

Nanofiltration (NF) can effectively remove a significant portion of salts and heavy metals from industrial water, especially divalent ions such as calcium, magnesium, and many heavy metal ions, with rejection rates often between 90% and 98% for these contaminants. However, NF typically allows partial passage of monovalent salts like sodium and chloride, so it does not achieve the near-complete salt removal characteristic of reverse osmosis (RO). In industrial wastewater treatment, NF is widely used because it balances high removal of hardness-causing ions, heavy metals, and organic pollutants with lower energy consumption and operating pressures compared to RO. Recent advances in NF membrane technology, including novel charge distributions, have improved salt permeation control and antifouling properties, enhancing NF’s effectiveness in treating high-salinity and complex industrial wastewaters. Therefore, NF is a cost-effective and energy-efficient choice for partial desalination and heavy metal removal in industrial applications, especially when complete salt removal is not required or when combined with other treatments like RO for polishing. It is particularly suited for recycling and reuse of industrial process water where selective ion removal and organic contaminant reduction are needed.

Can nanofiltration purify, concentrate, and filter process streams containing proteins and divalent ions from water?

Yes, nanofiltration can purify, concentrate, and filter process streams containing proteins and divalent ions from water. Nanofiltration membranes, with pore sizes typically between 1 and 10 nanometers, are effective in removing divalent ions such as calcium and magnesium, as well as larger organic molecules like proteins, while allowing smaller molecules like water and monovalent salts to pass through. This makes nanofiltration suitable for applications requiring the removal of specific contaminants while retaining certain components in the water stream.

How does the energy efficiency of nanofiltration compare to that of reverse osmosis?

Nanofiltration (NF) is generally more energy-efficient than reverse osmosis (RO) because it operates at lower pressures, resulting in lower energy consumption for applications that do not require complete desalination. RO requires higher pressure to achieve nearly total desalination, making it more energy-intensive. However, RO provides higher removal rates of dissolved salts compared to NF. Thus, NF is preferred for partial filtration with lower energy use, while RO is used when high-purity water is needed despite its higher energy demand.

How does nanofiltration compare to reverse osmosis and ultrafiltration in terms of operation and filtration performance?

Nanofiltration, reverse osmosis, and ultrafiltration differ in their operation and filtration performance. Nanofiltration uses less energy and operates at lower pressures compared to reverse osmosis, removing particles as small as 0.001 μm, including some dissolved solids and natural organic matter. It is often used for softening hard water and removing divalent ions. Reverse osmosis requires more energy but can remove particles as small as 0.0001 μm, effectively removing virtually all dissolved substances, making it ideal for producing highly purified water. Ultrafiltration removes larger particles, including bacteria, protozoa, and some viruses, but does not target dissolved solids. It operates at higher pressures than microfiltration but lower than nanofiltration and reverse osmosis.

What is the typical pore size range of nanofiltration membranes?

The typical pore size range of nanofiltration membranes is between 1 and 10 nanometers.

What pretreatment steps are necessary prior to nanofiltration or reverse osmosis processes?

Traditional pretreatment steps necessary prior to nanofiltration or reverse osmosis processes typically include sediment filtration to remove large particles, carbon filtration to eliminate volatile organic compounds and chlorine, water softening or antiscalant dosing to prevent scaling, and pH adjustment to ensure optimal membrane performance. Additionally, multi-media filtration systems and cartridge filters may be used to further reduce turbidity and particle size, protecting the membranes from fouling. Chemical dosing systems, such as chlorination or dechlorination, may also be applied to control biological growth and remove oxidizers that could damage the membranes. Microfiltration (MF) and ultrafiltration (UF) membranes are widely recognized as the best pre-treatment steps for nanofiltration (NF) and reverse osmosis (RO) systems, especially in industrial water treatment. Their ability to physically remove suspended solids, colloids, bacteria, viruses, and macromolecules ensures that feed water entering NF or RO is free of particles that could cause rapid membrane fouling or irreversible damage.

Could nanofiltration be effectively used for desalination purposes?

Yes, nanofiltration can be effectively used for desalination purposes, although it cannot remove 100% of salt like reverse osmosis. It is particularly useful as a pre-treatment to reduce scaling and optimize energy consumption, and it can remove a significant portion of dissolved salts, especially divalent ions like calcium and magnesium sulfate. Nanofiltration strikes a balance between desalination and mineral retention, often requiring less energy than reverse osmosis.

What contaminants can reverse osmosis effectively remove from water?

Reverse osmosis can effectively remove a wide range of contaminants from water, including dissolved salts, particles, colloids, organics, bacteria, pyrogens, heavy metals like lead, mercury, and arsenic, chemicals such as chlorine and pesticides, and certain "forever chemicals" like PFAS. However, it may not remove dissolved gases like carbon dioxide or radon, and additional systems like UV disinfection may be needed for complete microbial protection.

Why is high pressure necessary for reverse osmosis systems to function effectively?

High pressure is essential in reverse osmosis (RO) because it must overcome the natural osmotic pressure that pushes water from low to high solute concentration. By applying pressure typically between 55 and 85 bar (depending on feedwater salinity and temperature), RO systems force water molecules through a semi-permeable membrane while blocking dissolved salts, minerals, and contaminants. This pressure-driven process reverses the natural osmotic flow, enabling the production of purified water (permeate) and separating out concentrated waste (brine). Without sufficient pressure, water cannot pass effectively through the membrane, and contaminants would not be properly rejected. In summary, high pressure is essential to reverse the natural osmotic flow, drive water through the membrane, and achieve effective separation of contaminants, making it the core principle behind RO operation.

How can reverse osmosis membranes be effectively maintained and cleaned?

Effective maintenance of reverse osmosis (RO) membranes involves several key steps tailored to the feedwater quality and system use: Monitor system performance (track parameters like flow rate, pressure, and salt rejection to detect fouling or membrane degradation early). Chemical cleaning (CIP): (clean membranes periodically with appropriate acidic or alkaline solutions to remove inorganic scaling, organic fouling, and biofilms. Cleaning frequency depends on feedwater characteristics and fouling severity). Proper shutdown and preservation (during downtime, flush membranes regularly or use preservation solutions to prevent microbial growth and membrane damage). Use manufacturer-approved chemicals and follow recommended protocols to avoid membrane damage and ensure effective cleaning. Implement preventive maintenance schedules based on pilot testing and operational data to optimize cleaning intervals and extend membrane life. By combining these practices, industrial RO systems maintain high efficiency, reduce downtime, and prolong membrane lifespan.

Can reverse osmosis systems be used for industrial applications in the chemical, pharmaceutical, and food industries?

Yes, reverse osmosis systems can be used for industrial applications in the chemical, pharmaceutical, and food industries. They are particularly useful for producing highly purified water necessary for drug manufacturing and laboratory processes in the pharmaceutical industry. In the food and beverage industry, RO systems ensure the removal of contaminants to maintain product quality. Additionally, in chemical plants, RO systems treat wastewater, allowing for its reuse and reducing environmental impact.

How sustainable is reverse osmosis as a method for water purification and reuse?

Reverse osmosis (RO) is generally considered a sustainable method for water purification and reuse due to several factors. It reduces water waste by achieving high recovery rates, often between 75% and 90%, and minimizes the use of harsh chemicals, contributing to a cleaner process. However, they do generate brine waste and require significant energy, though newer models are more energy-efficient. Overall, RO systems support sustainable water management by conserving resources and reducing environmental impact.

What factors influence the lifespan of nanofiltration and reverse osmosis membranes?

The lifespan of nanofiltration and reverse osmosis membranes is influenced by several key factors: the quality of the feed water (including levels of contaminants like chlorine, salts, minerals, iron, manganese, and organic matter), the effectiveness of pretreatment systems (such as UF or sediment and carbon filters), system usage intensity, and maintenance practices including regular cleaning, sanitization, and monitoring for fouling or scaling. Proper pretreatment and maintenance can significantly extend membrane life, which typically ranges from 2 to 5 years but varies depending on these conditions.