Modular construction on chemical process system

01 August 2017

Modular construction on chemical process system

In the chemical, specialty chemical and pharmaceutical industries, the cost of capital projects is on the rise.

The time-to-market for a new product is critical, which minimises the time available for design and construction of the chemical process system. The quest is to find the most cost-effective and fast-track approach to project execution. The solution (answer) is Pfaudler’s modular design/construction.

Typical Plant Construction - Critical issues

Many operating plants have downsized both their process and project engineering departments. Staff engineers are overloaded with work and only have time to execute small projects. Medium to large-size projects are typically outsourced. One or more engineering design firms are hired to design and/or manage the project. Many different vendors are used to source all the equipment, instrumentation, piping and specialty components that comprise the process system. Many contractors for each of the various construction disciplines are contracted to complete the construction work on site. While this is the typical project execution approach, there are inherent problems that increase costs and cause schedule delays.

With so many parties involved, the risks and problems with the execution of the project rise, increasing the cost and causing schedule delays. When problems arise, the parties often begin the finger-pointing blame game. The separate design by various parties of the many individual components often produces unsuitable design and poor system integration and thus incorrect functionality, due to lack of a single point of oversight. Finally, with so many parties involved, the cost is increased through stacked margins.

For plants located in remote areas or in areas where much construction is underway, there are often labour shortages and it is difficult to find local, qualified, high quality contractors for all the construction disciplines. This forces the use of non-local contractors which increases costs through the living and/or travel expenses incurred.

Weather delays are frequent as weather always plays a factor in green-field and/or outdoors plant construction.

For indoor installations in existing facilities, there are substantial hidden lost production costs due to construction interruptions of adjacent processes.

Pfaudler Modular Process System Design/Construction – The solution

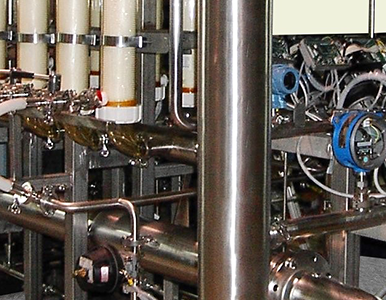

Pfaudler provides single-source responsibility for your process system from the design of the system through to construction of the system in a modular form, plus the installation of the module(s) and commissioning at your plant site. The modular design/build concept is implemented for any type of process system whether it is a reaction, filtration, evaporation, distillation, etc. one. A complete modular process system includes all of the process equipment mounted in structural steel frames with the all interconnecting process and utility piping and instrumentation fabricated/installed as a complete assembly. A modular process system also includes all the intangible, but critical components of a successful project including: engineering, specifications, design, HAZOP, project engineering, project management, cost control, schedule control, commissioning, documentation, training and post-startup service and parts.

Modular design - The benefits

Fixed Price

Pfaudler provides firm, fixed pricing for process modules because the scope of work for modular design is well-defined and fixed. Also, the greater the amount of scope of work included in the module, the greater the overall project cost reduction and control. This eliminates field work estimating any unforeseen costs at the end of the project.

Single Source Responsibility

Pfaudler takes full, single-source responsibility starting with design, through to construction, commissioning and training. This minimises the communication lines, prevents problems, reduces costs and allows for efficient, fast-track project execution. This also ensures that all the components of the system are designed and manufactured correctly for a fully integrated and fully operational system. Should a problem arise during construction or commissioning, our single-source responsibility eliminates any “finger pointing” and accelerates the resolution of the problem and reduces costs.

Fast Track Projects with Quality Construction

Pfaudler has all its engineering and fabrication disciplines in-house. They have been working together for many years, designing and building modules. Great inter-discipline communication and cooperation between engineering disciplines and construction disciplines provides for fast-track project schedules and fewer problems and associated costs. Our modules are manufactured and assembled in our climate-controlled shops, where more and better tools are within easy reach, allowing us to provide our clientele with higher quality construction. Shop construction is much more efficient than field manufacturing, which allows for fast-track construction.

Significantly lower installation and overall project costs

Shop labour is much more efficient than field labour due to the controlled working environment, the availability of better and more tools/machines/material, and because all other site work delays (for example, work permits) are eliminated. The same amount of work completed in less time means a lower cost.

Reduced downtime for installation

Much less downtime is required for module installation versus stick build projects and this minimises production downtime in adjacent processes and minimises lost production.

Pfaudler is ready to design and build your next process system.

Contact Pfaudler today to learn more