Reactor System Lab Fast Pro Rethinking the LAB System - 1 up to 10 litres

06 November 2020

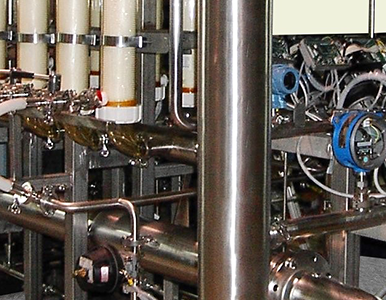

Reactor System Lab Fast Pro Rethinking the LAB System - 1 up to 10 litres

Time-to-market for a new system plays a major role in developing solutions for the critical needs of our clients.

The NORMAG LAB reaction units, filter and filter reactor system can be the solutions for rebuilt equipment in just a few steps without the need for any tools, thus saving space, costs and time.

Thanks to the triple holders Basic and Pro, the bowl and hood can be changed independently of each other. The large selection of components and almost unlimited choice of connection options allows great freedom for customization and later expansion. Since we at NORMAG always rely on widespread standard flanges and cuts, we can also use existing accessories.

Just as future-oriented and customizable is the associated control and data storage CU Pro2, which can be coupled with many laboratory devices (pumps, scales, ...), sensors and actuators.

Access is via WiFi or LAN can be done by PC / Mac / Smartphone / Tablet.

Our engineers and technicians work closely with you to assist in selecting the right solution and then optimizing it for your process conditions.

Advantages

- Flexible system that saves space, costs and time;

- Triple holder enables fast, independent conversion of vessels and hood;

- Thanks to standard ground joints and flanges, existing accessories can be used;

- Connection to other laboratory devices by control unit CU Pro2;

- Data storage and recipe management

Components & Options for your version of the Reactor System Lab Fast Pro

Agitator

We offer all common laboratory overhead stirrers and stirrers

Stirring coupling

- Stirrer coupling basic

- Stirring coupling pro with mechanical seal

- Magnetic coupling up to 400 Ncm

Thermoblocks

- For easy and quick change of the vessels

- Allows comfortable draining of tempering oil

Distillation top

- Distillation top basic with manual return divider, reflux condenser up to 0.3 m², various collecting flasks or distributor

- Distillation top pro with electromagnetically controlled return divider, reflux condenser up to 0.3 m², various collecting flasks or distributors, CU easy for control (not applicable with CU Pro2)

Control and data backup

- CU Pro2 with integrated control, data backup and recipe management (optional)

- Many thermostats, vacuum pumps, liquid pumps, agitators, scales, sensors, ... compatible

- Control can be adapted again and again to new needs

- Based on Beckhoff industrial components

- Connection via WiFi or LAN to any browser-capable device, in the example pictured is a Surface Tablet

- Data backup as Excel file

Reaction vessels

- 0.1 to 5 l, with DN 100, 150 and 200, with and without tempering jacket and vacuum insulation, all graduated vessels and 1.25: 1 ratio for scale-up experiments

- Connections for temperature control optimized for idling the temperature control

- Temperature control jacket optimized for better heat transfer

- NORMAG bottom drain valve optimized for dead space and easy to clean, with integrated compression spring for leak-tightness at all temperatures

- Temperature control connections DN 15 for high flow rates without congestion and optimized heat transfer

Filter reaction vessels

- 0.1 to 5l, with DN 100, 150 and 200

- Temperature control jacket with NORMAG deflectors for best heat transfer into the flange, without cold bridges

- Temperature control connections DN 15 for high flow rates without congestion and optimized heat transfer

- Filter plate hold up optimized and quickly changeable without tools

- •Different filter papers or fabrics can be used

Filter vessels

- 0.1 to 5l, with DN 100, 150 and 200

- Filter plate hold up optimized and quickly changeable without tools

- Different filter papers or fabrics can be used

Contact Pfaudler today to learn more: Martin.Kuchorz@pfaudler.com